MES/MOM

At Cogiscan, we believe factory digitalization shouldn’t be complicated. To better support that mission, we've broadened our product portfolio to also sell iTAC Software AG's MES/MOM suite to help you transform your manufacturing operation from the ground up.

Ranging from a machine-connectivity only solution for legacy equipment to a factory-wide, complete turnkey MOM installation & everything else in between...

No matter where you are on the road to factory digitalization, we have a solution for you.

Ranging from a machine-connectivity only solution for legacy equipment to a factory-wide, complete turnkey MOM installation & everything else in between...

No matter where you are on the road to factory digitalization, we have a solution for you.

MES/MOM

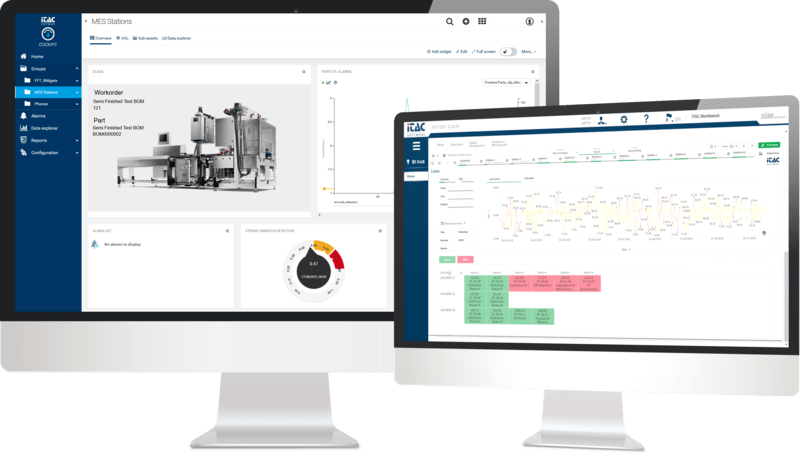

Manufacturing Execution

The Manufacturing Execution system from iTAC Software AG will ensure your factory is always performing as intended – with real-time production data you’ll guarantee you are running the right products with the right materials in the most optimal conditions. Covering the various requirements of production, from order execution all the way to final delivery.

Based on a composable architecture, the modules within this system integrate seamlessly into existing manufacturing ecosystems.

Based on a composable architecture, the modules within this system integrate seamlessly into existing manufacturing ecosystems.

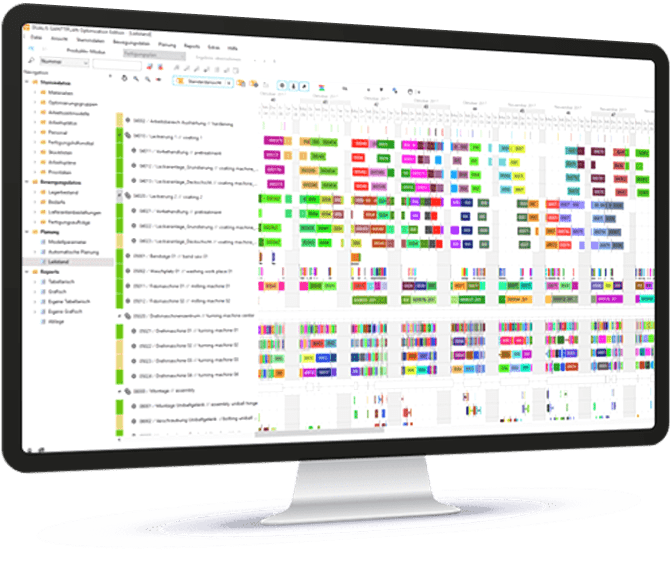

Advanced Planning & Scheduling (APS)

The Advanced Planning and Scheduling (APS) system from iTAC Software AG enables factories to achieve a smooth work order flow with shorter lead times and continuous cost optimization.

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Business Intelligence & IIoT.Edge (AI)

The Business Intelligence and AI offering from iTAC Software AG provides a scalable platform of complete manufacturing intelligence. Accurately and automatically collecting and contextualizing production data, these solutions provide invaluable predictive analytics to help improve your overall efficiency and performance.

Used by manufacturers worldwide, these intuitive, web-based dashboards provide actionable insights to drive better decision making and properly align your manufacturing operation for the future.

Used by manufacturers worldwide, these intuitive, web-based dashboards provide actionable insights to drive better decision making and properly align your manufacturing operation for the future.

iTAC.MOM.Suite

Complete ERP Synchronization:

ERP

To ensure that inventory is planned and managed appropriately based on actual usage, we include real-time synchronization with your ERP, or other 3rd-party material management software system.

Other industries served beyond electronics assembly

Automotive

E-Mobility

Cable

Processing

Processing

Medical

(MedTech)

(MedTech)

Injection

Molding

Molding

Metal

Casting

Casting

Get personalized guidance from our experts

Factory Digitalization is very specific to each factory – and typically looks different for every customer. With our team of experts, we have years and years of combined industry knowledge and experience – and our experts are happy to offer tips and recommendations to get your digitalization efforts underway. Connect with them today and experience the "Cogiscan effect"!

Talk to an Expert

© 2021 Cogiscan. Tous droits réservés.

+ 1-450 534-2644

+ 1-877-534-2644 (USA and Canada only)

+ 1-877-534-2644 (USA and Canada only)

28-B boulevard de l’Aéroport

Bromont (Quebec), Canada J2L 1S6

Bromont (Quebec), Canada J2L 1S6