Optimizing production is a constant challenge as you must equally balance the requirements of materials, machines, tools & operators. When everything is changing quickly, adaptability is key for every factory to meet its max potential.

The Advanced Planning and Scheduling (APS) system from iTAC Software AG enables factories to achieve a smooth work order flow with shorter lead times and continuous cost optimization.

The Advanced Planning and Scheduling (APS) system from iTAC Software AG enables factories to achieve a smooth work order flow with shorter lead times and continuous cost optimization.

// iTAC.MOM.Suite

Advanced Planning & Scheduling (APS)

Planning & Scheduling

Automatic Replanning

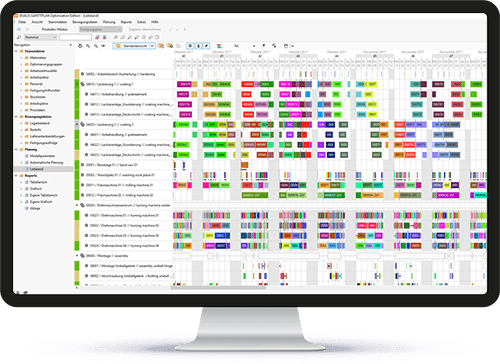

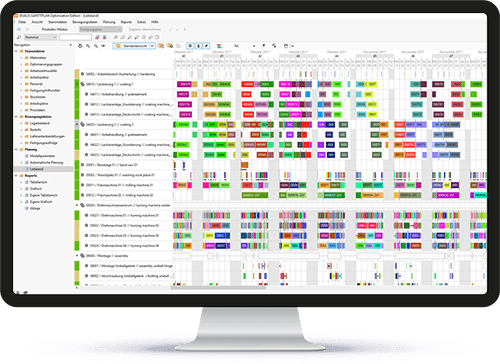

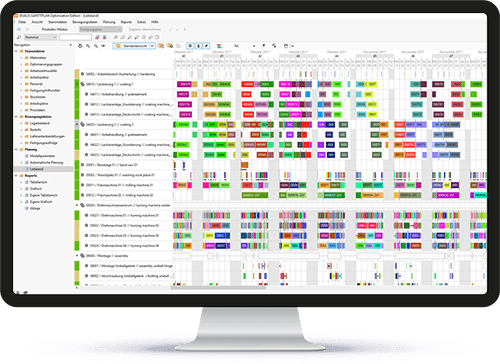

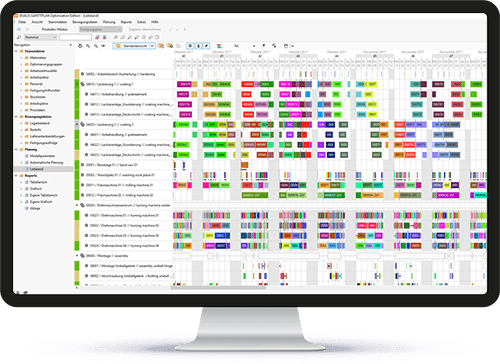

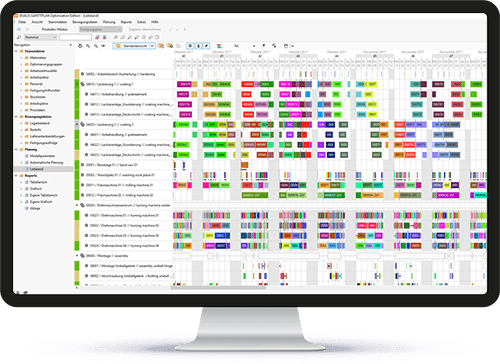

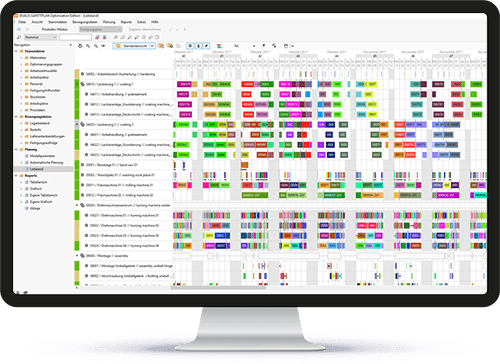

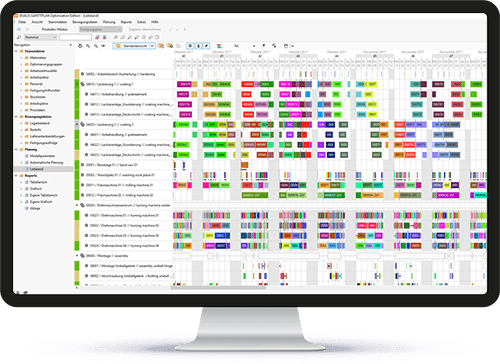

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Our APS tool offers automatic re-planning when you face unexpected issues.

Planning & Scheduling

Automatic Replanning

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Our APS tool offers automatic re-planning when you face unexpected issues.

100% Configurable

You can fully configure your scheduling priorities, including:

- your machine capabilities,

- the qualifications of your operators,

- the real-time availability of materials on your shop floor.

Planning & Scheduling

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Real-Time Monitoring

Our APS application monitors resource availability in real-time so you can make the right decision, every time.

Planning & Scheduling

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Drag-and-Drop Editing

You can manually change the schedule using the drag-and-drop interface (GUI).

Planning & Scheduling

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Detailed Information

Our APS application offers detailed information on

- machines,

- materials,

- tools,

- and employees.

Planning & Scheduling

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Gantt-Chart View

The main screen of the APS tool is the gantt-chart view: displaying current status of all machines, employees’ shifts & breaks, as well as color-coded production orders.

Planning & Scheduling

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

Gantt-Chart View

The main screen of the APS tool is the gantt-chart view: displaying current status of all machines, employees’ shifts & breaks, as well as color-coded production orders.

Planning & Scheduling

Clearly visualizing results on the graphical production control station, this software enables you to optimally plan all orders based on available resources and capacities, while accounting for both schedule and cost requirements.

+150

About our APS software

companies are using our software worldwide

30%

increase in overall throughput

Get personalized guidance from our experts

Factory Digitalization is very specific to each factory – and typically looks different for every customer. With our team of experts, we have years and years of combined industry knowledge and experience – and our experts are happy to offer tips and recommendations to get your digitalization efforts underway. Connect with them today and experience the "Cogiscan effect"!

Main benefits

Optimize Production:

With the ability to optimally plan all production orders based on real-time resource availability and capacity, you can leverage dramatic improvements to your factory's uptime, utilization and OEE.

Go From Rough To Fine:

More than just a high-level schedule overview, APS calculates all considerations – balancing on-time delivery, resource availability & cost savings – to produce an optimal schedule based on the specifics of your factory goals.

Fast & Agile Scheduling:

An intelligent scheduling system allows you to react quickly and change your schedule on the fly when necessary. Quickly plan how to cover a missed, or hot new drop-in, production order.

“We now have much greater transparency and responsiveness in our planning and scheduling. We can say quite clearly that the APS tool has helped us optimize inventories and increased our customer satisfaction and competitiveness.”

Talk to an Expert

© 2021 Cogiscan. Tous droits réservés.

+ 1-450 534-2644

+ 1-877-534-2644 (USA and Canada only)

+ 1-877-534-2644 (USA and Canada only)

28-B boulevard de l’Aéroport

Bromont (Quebec), Canada J2L 1S6

Bromont (Quebec), Canada J2L 1S6