Business Intelligence

The Business Intelligence and AI offering from iTAC Software AG provides a scalable platform of complete manufacturing intelligence. Accurately and automatically collecting and contextualizing production data, these solutions provide invaluable predictive analytics to help improve your overall efficiency and performance.

// iTAC.MOM.Suite

Business Intelligence

Business Intelligence

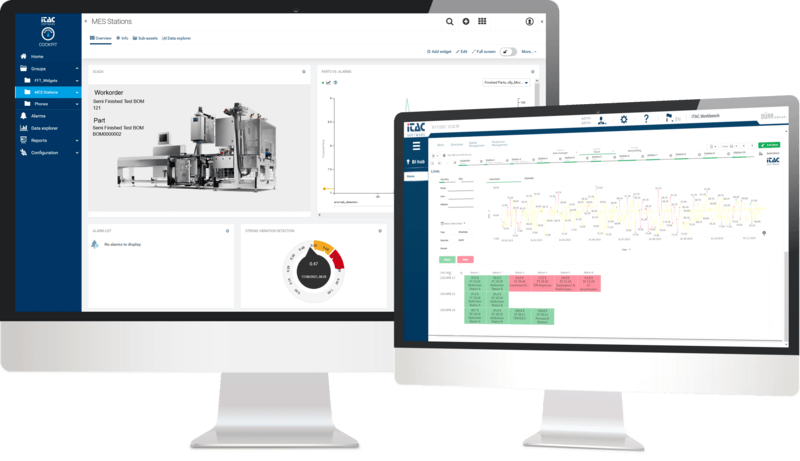

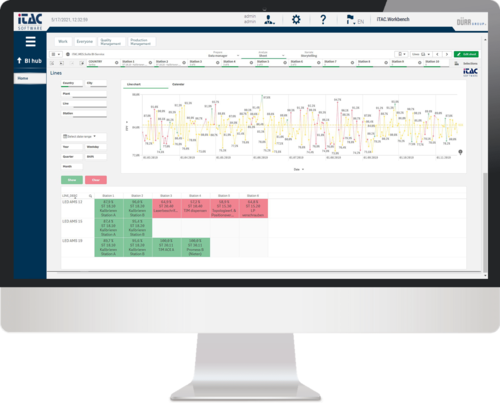

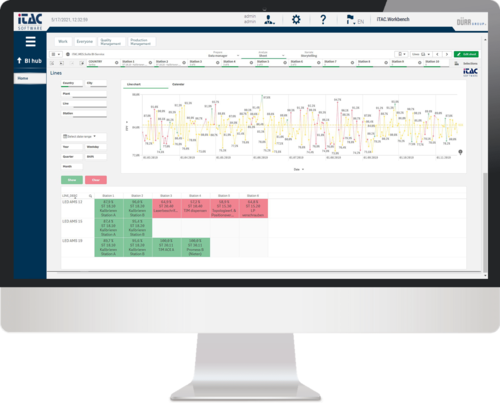

Simplified Data Analysis

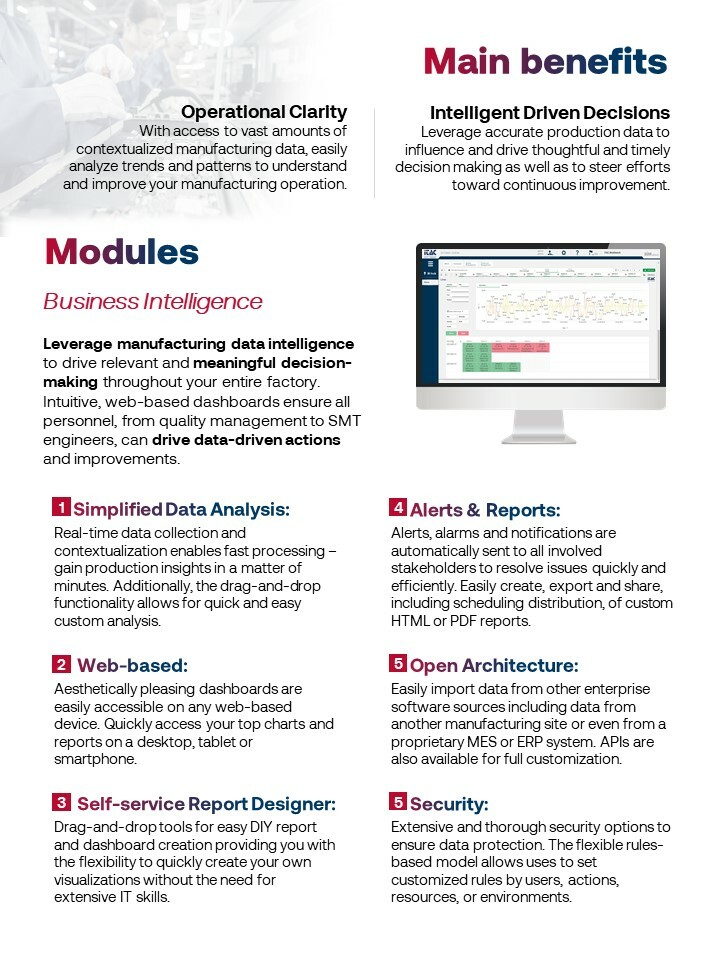

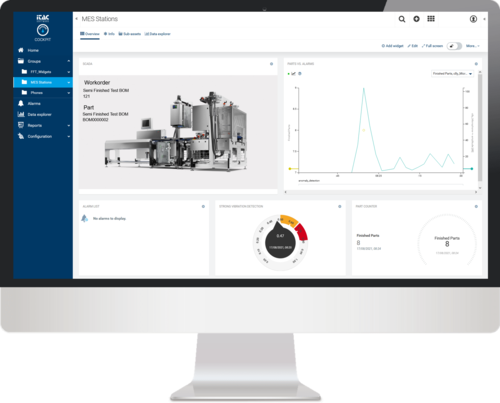

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Real-time data collection and contextualization enables fast processing – gain production insights in a matter of minutes. Additionally, the drag-and-drop functionality allows for quick and easy custom analysis.

Business Intelligence

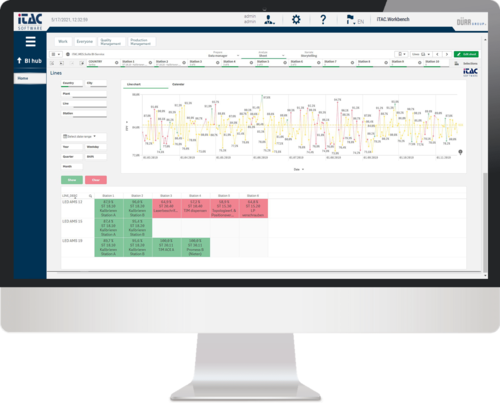

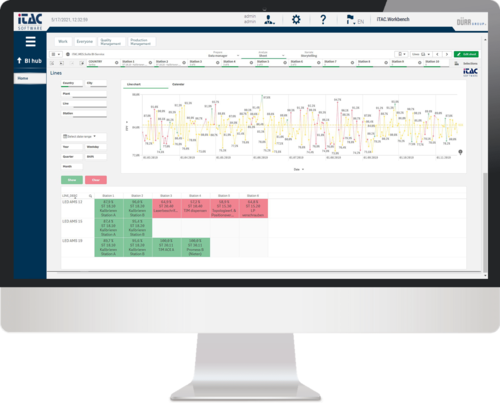

Simplified Data Analysis

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Real-time data collection and contextualization enables fast processing – gain production insights in a matter of minutes. Additionally, the drag-and-drop functionality allows for quick and easy custom analysis.

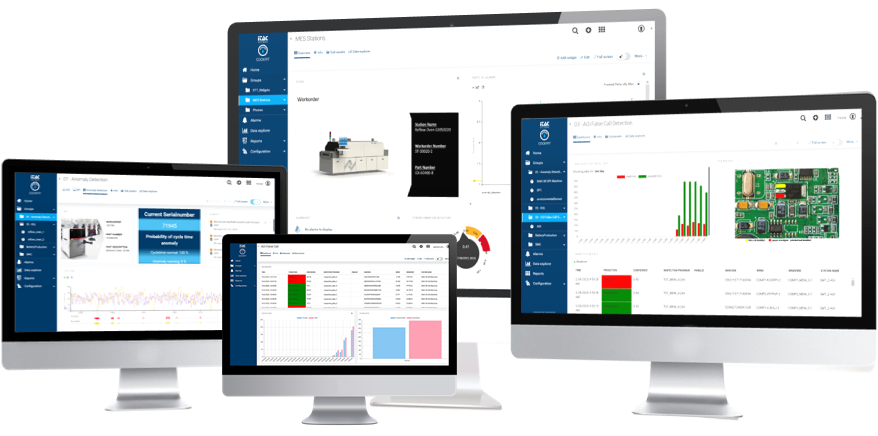

Web-based Application

Aesthetically pleasing dashboards are easily accessible on any web-based device. Quickly access your top charts and reports on a desktop, tablet or smartphone.

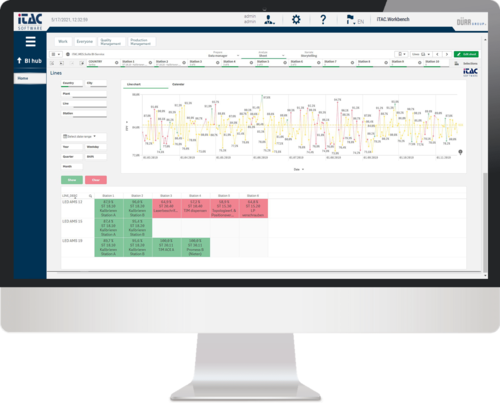

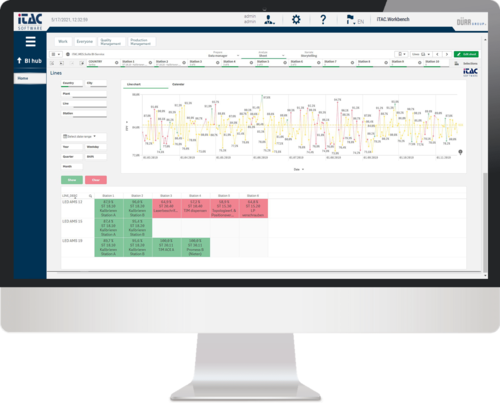

Business Intelligence

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Self-service Report Designer

Drag-and-drop tools for easy DIY report and dashboard creation provide you with the flexibility to quickly create your own visualizations without the need for extensive IT skills.

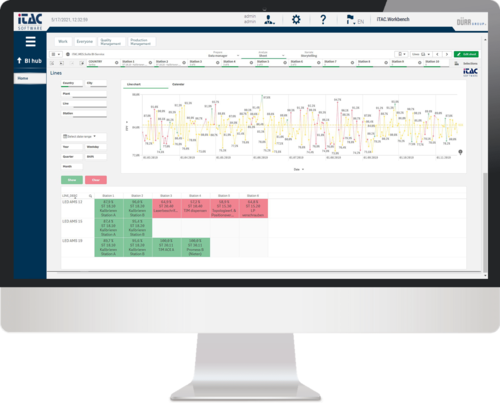

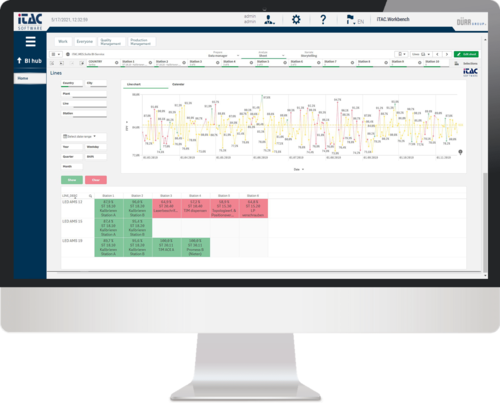

Business Intelligence

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Alerts & Reports

Alerts, alarms and notifications are automatically sent to all involved stakeholders to resolve issues quickly and efficiently. Easily create, export, and share, including scheduling distribution of, custom HTML or PDF reports.

Business Intelligence

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Open Architecture

Easily import data from other enterprise software sources including data from another manufacturing site or even from a proprietary MES or ERP system. APIs are also available for full customization.

Business Intelligence

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Security

Extensive and thorough security options to ensure data protection. The flexible rules-based model allows users to set custom rules by users, actions, resources, or environments.

Business Intelligence

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

Security

Extensive and thorough security options to ensure data protection. The flexible rules-based model allows users to set custom rules by users, actions, resources, or environments.

Business Intelligence

Leverage manufacturing data intelligence to drive relevant and meaningful decision-making throughout your entire factory. Intuitive, web-based dashboards ensure all personnel, from quality management to SMT engineers, can drive data-driven actions and improvements.

IIoT.Edge

(AI)

Gain even deeper insight into everything happening on the production floor by combining all manufacturing data into one AI-based platform – taking you from descriptive to prescriptive analytics. This integrated machine learning technology helps to eliminate problems before they happen, meaning the IIoT.Edge has the potential to revolutionize your production operation.

Get personalized guidance from our experts

Factory Digitalization is very specific to each factory – and typically looks different for every customer. With our team of experts, we have years and years of combined industry knowledge and experience – and our experts are happy to offer tips and recommendations to get your digitalization efforts underway. Connect with them today and experience the "Cogiscan effect"!

Popular Combo

Co-NECT

Factory Intelligence

IIoT.Edge

Used to feed rich data from SMT machines to Factory Intelligence and IIoT.Edge. Can also be used to interlock machines and to enable closed-loop self-correcting systems.

Learn More!

Learn More!

Out-of-the-box real-time and historical dashboards for visualization of quality, availability, and performance metrics, with drill downs for detailed root cause analysis.

Learn More!

Learn More!

Powerful AI and Machine Learning platform for predictive analytics, with real-time monitoring and alerting, and low-code device integration and model building tools

Learn More!

Learn More!

Modular Solutions:

!

Cogiscan's and iTAC Software's solutions are 100% modular. This means that you can pick and choose the ones you actually need. Implementation is scalable too – grow as slowly or quickly as you'd like.

Talk to an Expert

© 2021 Cogiscan. Tous droits réservés.

+ 1-450 534-2644

+ 1-877-534-2644 (USA and Canada only)

+ 1-877-534-2644 (USA and Canada only)

28-B boulevard de l’Aéroport

Bromont (Quebec), Canada J2L 1S6

Bromont (Quebec), Canada J2L 1S6