Powerful AI-based solution for fast & simple optical inspection with defect & repair management. TTC Fix reduces defects at manual assembly by 90%!

Our TTC Fix platform offers a robust and powerful solution for complete pre-solder defect management. Centered on the Focus AI station, a 2D inspection machine powered by an AI and machine-learning platform, its neural network quickly detects the most common errors for THT components placed in manual assembly. Further enhanced by Cogiscan’s TTC Server software, TTC Fix includes an intuitive, visual repair tool as well as full traceability reporting of all defects including image files.

TTC Fix

// AI-Based Solution for Inspection

Features

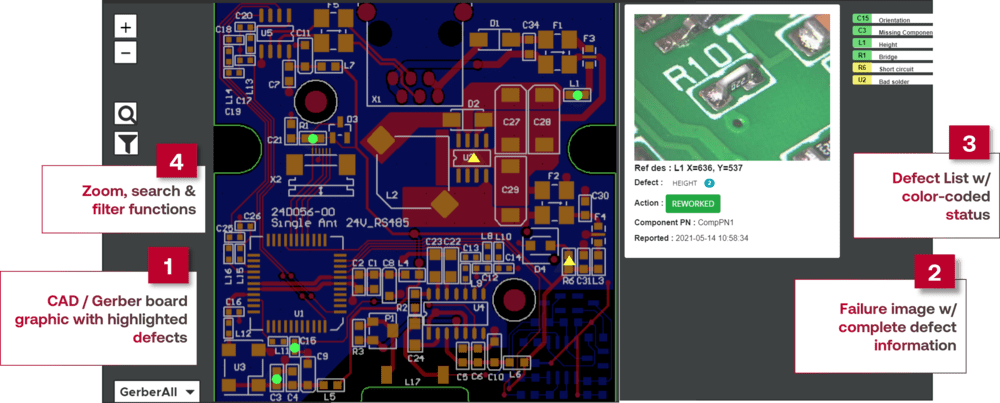

Digital Repair Station

TTC Fix includes a Digital Rework Station with visual and intuitive instructions.

Among other features, it includes:

- A visual representation of the board using standard files like CAD or Gerber with highlighted defects.

- Failure image with complete defect information

- Defect list with color-coded status

- Zoom, search and filter functions.

Features

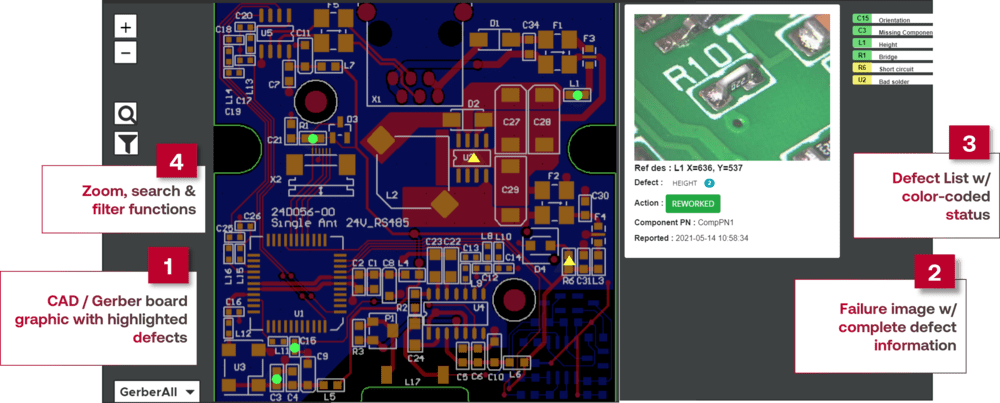

Digital Repair Station

TTC Fix includes a Digital Rework Station with visual and intuitive instructions.

Among other features, it includes:

- A visual representation of the board using standard like CAD or Gerber with highlighted defects.

- Failure image with complete defect information

- Defect list with color-coded status

- Zoom, search and filter functions.

Features

Inspection Data Management

TTC Fix uses Cogiscan's TTC Server software to centralize defect data and store them in a single place.

You can also easily share inspection results data with other enterprise systems, such as your MES or ERP.

You can also easily share inspection results data with other enterprise systems, such as your MES or ERP.

Features

Traceability

TTC Fix includes full traceability of inspection results, including defect codes and images.

This feature enables compliance by maintaining a complete history of all inspections, defects & repairs.

This feature enables compliance by maintaining a complete history of all inspections, defects & repairs.

Features

Focus AI Station

The Focus AI machine is a 2D inspection station used prior to soldering (THT) to make sure you find and fix error before they become real defects soldered onto the product.

NPI is done with AI algorithms and can be done under 5 minutes without any engineering skills.

The Focus AI Station can be purchased standalone without our TTC software.

NPI is done with AI algorithms and can be done under 5 minutes without any engineering skills.

The Focus AI Station can be purchased standalone without our TTC software.

Features

AI Algorithms

TTC Fix is powered by an AI & machine-learning platform and uses a neural network to quickly detect the most common errors for THT.

AI algorithms perform both programming & inspection.

AI algorithms perform both programming & inspection.

Features

AI Algorithms

TTC Fix is powered by an AI & machine-learning platform and uses a neural network to quickly detect the most common errors for THT.

AI algorithms perform both programming & inspection.

AI algorithms perform both programming & inspection.

90%

Reduce defects by

What to expect?

Notes: This study was performed at a large EMS in Europe - measurement were done post-soldering of THT components.

at manual assembly

51%

Reworks down by

Notes: From 11000 PPM to 5400 PPM after a 9-month project.

after a 9-month implementation

Benefits

Fast & Easy NPI:

No engineering skills required to program new products – intelligent & automatic programming in less than 5 mins.

Pre-Solder Detection & Correction:

Find and fix errors early, before they become real defects for both THT and SMT components.

Streamline Repair Process:

Simplify and centralize digital repair & rework with user-friendly visual work instructions.

Full Traceability:

Enable compliance with a complete history of all inspections, defects & repairs.

Low-Cost Inspection Option:

Affordable alternative to manual inspection. TTC Fix comes at a cheaper price than a standard AOI, and comes with the added cost reduction of fixing errors before soldering.

Get personalized guidance from our experts

Factory Digitalization is very specific to each factory – and typically looks different for every customer. With our team of experts, we have years and years of combined industry knowledge and experience – and our experts are happy to offer tips and recommendations to get your digitalization efforts underway. Connect with them today and experience the "Cogiscan effect"!

Focus AI station can be bought standalone

The Focus AI is a 2D inspection station powered by an AI and machine-learning platform, uses a neural network to quickly detect the most common errors for THT and SMT. Monitoring the quality of component assembly process, the Focus AI station flags potential defects and ensures correction before the repair becomes too cumbersome or impossible to correct.

Integration with our TTC Fix software is optional.

Integration with our TTC Fix software is optional.

"Using the Focus AI machine in production for our EMS Lighting Division, we experienced a 90% reduction in defects found at manual assembly (measured post-soldering). This early detection of defects leads to a tremendous savings for us - we no longer waste as much time and resources on retouching, fixing or even scrapping PCBAs."

~Slawomir Maslo´n, Engineering Vice Director

~Slawomir Maslo´n, Engineering Vice Director

Talk to an Expert

© 2021 Cogiscan. Tous droits réservés.

+ 1-450 534-2644

+ 1-877-534-2644 (USA and Canada only)

+ 1-877-534-2644 (USA and Canada only)

28-B boulevard de l’Aéroport

Bromont (Quebec), Canada J2L 1S6

Bromont (Quebec), Canada J2L 1S6